APPLICATIONS

Application driven solutions

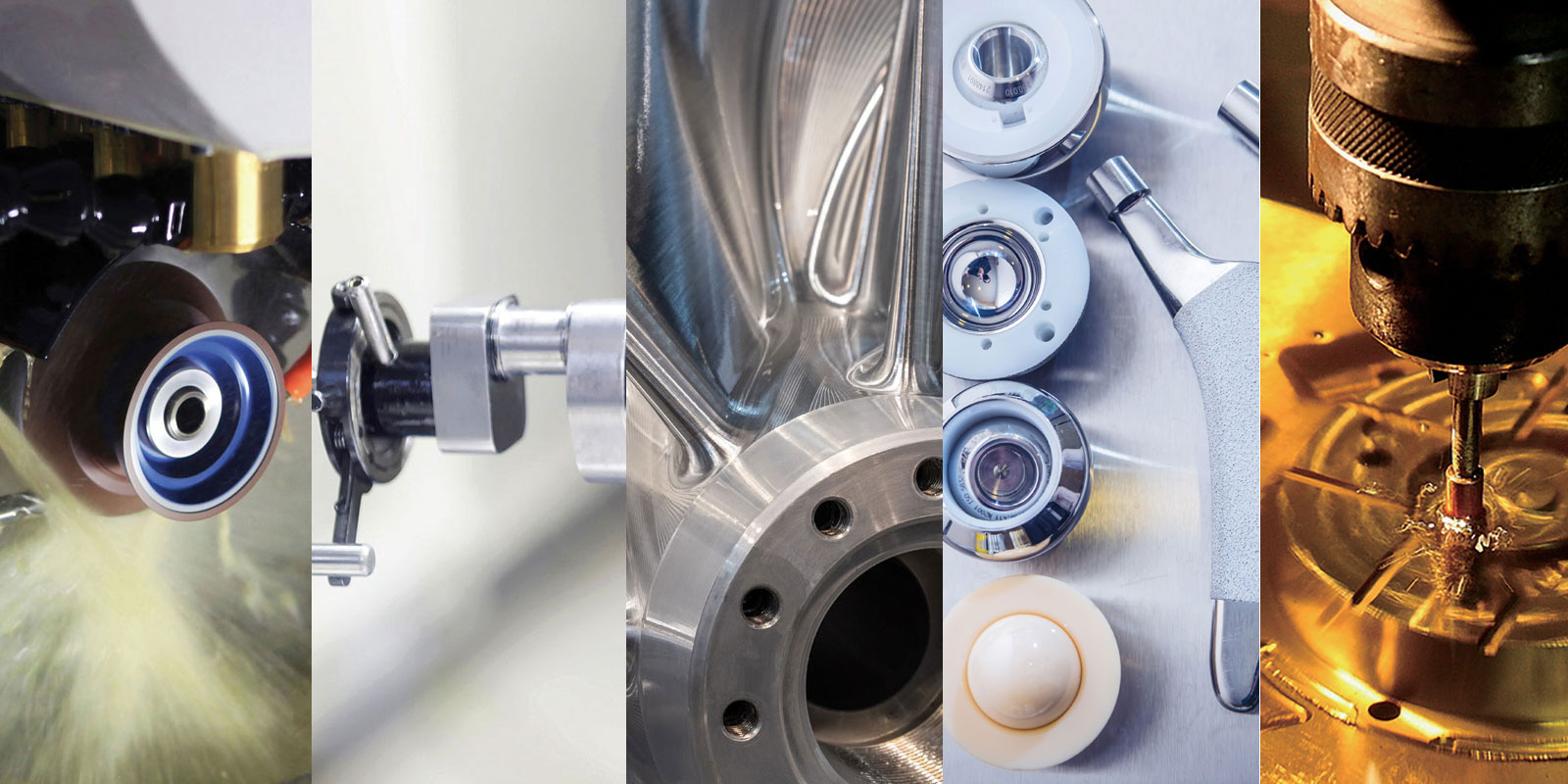

Ultra-Fine Filtration for All Your Applications

Ultra-Fine Filtration for Grinding, Machining, Aerospace, Medical & EDM

TRANSOR provides a solution in a variety of precision machining applications such as honing, bearing grinding, gear grinding, single/double disc grinding, lapping, ID/OD grinding and many others. TRANSOR’s ultra-fine filtration provides many benefits in the machining of a wide range of automotive and aviation components including crankshafts, camshafts, bearings, nozzles, engine blocks, rotors, etc.

CUTTER TOOL GRINDING

PRECISION MACHINING

AEROSPACE-DEFENSE

MEDICAL

EDM

Application Driven Solutions…by TRANSOR

CUTTER TOOL GRINDING

With particles greater than one micron filtered out of the dielectric oil, TRANSOR UFF technology enables mold processing to achieve faster, more accurate results. With a continuous supply of temperature controlled, UFF filtered dielectric, EDM operators have discovered they can stay “in the cut” twice as long combined with finer surfacefinishes.

While individual results will differ based on machining parameters, TRANSOR users typically experience production efficiencies ranging from 25% – 35%. It is easy to see why the payback on a TRANSOR unit is less than two years in most instances.

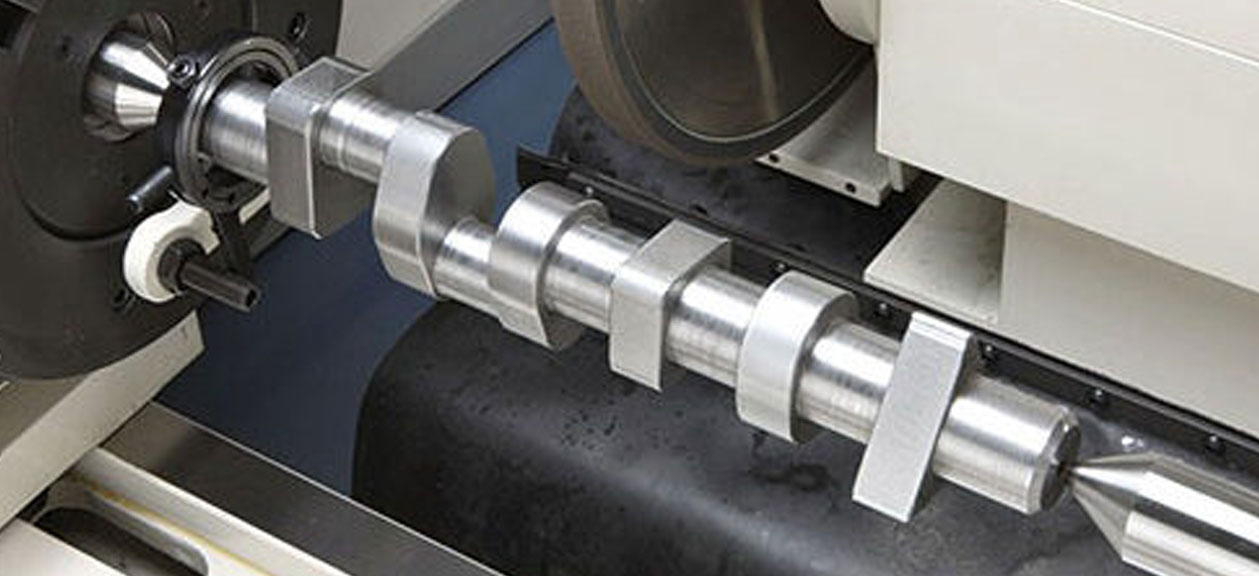

PRECISION MACHINING

TRANSOR users worldwide have seen the benefits of UFF for a variety of precision machining applications such as honing, bearing grinding, gear grinding, single/double disc grinding, lapping, ID/OD grinding and others.

Having a TRANSOR with oil filtered to Ultra-Fine and temperature control delivers the consistent machine environment manufacturers require. The results are closer tolerances, improved dimensionality, finer surface finishes all with faster cycle times. TRANSOR’s Ultra-Fine Filtration positively impacts the machining of a range of automotive and aerospace components crankshafts, cams, bearings, nozzles, engine blocks, rotors, etc.

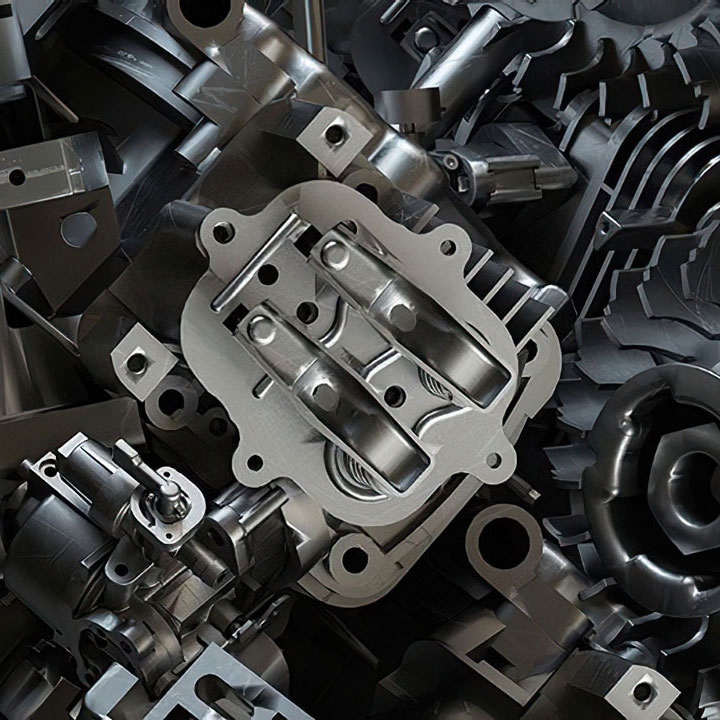

AEROSPACE/DEFENSE

Manufacturing precision components for the aerospace and defense industries requires holding extremely close tolerances. TRANSOR Filter Systems meet these demands for Ultra-Fine Filtration in a myriad of machining processes such as lapping andinternal tool making. Having this level of filtration provides significant benefits in faster cycle times, a cleaner work environment while contributing to minimizing cost over runs and re-works.

By removing contaminants from the coolant, TRANSOR systems provide a continuous supply of clean fluid to the machining process. In addition, temperature expansion of components, delivers repeatable machining results and increases the life span of machine components and systems.

MEDICAL EQUIPMENT

TRANSOR Filter Systems provide machining benefits to two significant areas of the medical equipment area. With the industry’s rapid growth and on-going developments, the benefits of having Ultra-Fine Filtration in manufacturing specialized tooling used in orthopedic implants, bone and plate screws, surgical instruments results in finer tool finishes, increased cycle time and lower machine maintenance.

In addition, with medicalcomponents that have complex geometries, TRANSOR systems provide the competitive edge in machining enabling repeatable performance, closer tolerances and reduced re-works.

EDM

With particles greater than one micron filtered out of the dielectric oil, TRANSOR UFF technology enables mold processing to achieve faster, more accurate results. With a continuous supply of temperature controlled, UFF filtered dielectric, EDM operators have discovered they can stay “in the cut” twice as long combined with finer surface finishes.

While individual results will differ based on machining parameters, TRANSOR users typically experience production efficiencies ranging from 25% – 35%. It is easy to see why the payback on a TRANSOR unit is less than two years in most instances.

Transor Delivers a Significant Competitive Edge to

Precision Machining Manufacturers.

Experience faster cycle times, reduced machine downtime, more precise cuts…virtually maintenance free.

TRANSOR's Total Cost Of Ownership

It Makes Dollars and Sense For Your Operation.

Get more information. Submit form or call.

Call Us

847-640-0273

Please direct your inquires to one of the following departments based on your question, and we will be happy to assist you.

Hours of Operation: M-F 8:30AM-4:30PM (CST)

ORDER DESK:

(Spare Parts/Oil quotes, Parts/Order Inquiry, Submitting PO's)

ORDER DESK:

(Spare Parts/Oil quotes, Parts/Order Inquiry, Submitting PO's)

Office Location

3000 Malmo Drive

Arlington Heights, IL 60005, USA

Open Hours

M-F: 8am - 5pm

info@transorfilter.com